Umsebenzi oyinhloko we-umshini wokusonta indwangu engalukiweukuvunguza izinto zendwangu engalukiwe enobubanzi obubanzi zibe imiqulu ngenjongo yokugcina, ukuthutha, nokucubungula okulandelayo.

Imvamisa, umshini wokusonta uxhumeke neminye imishini kulayini wokukhiqiza indwangu engalukiwe, njengemishini yokudonsa kanye nemishini ye-hydroentanglement.

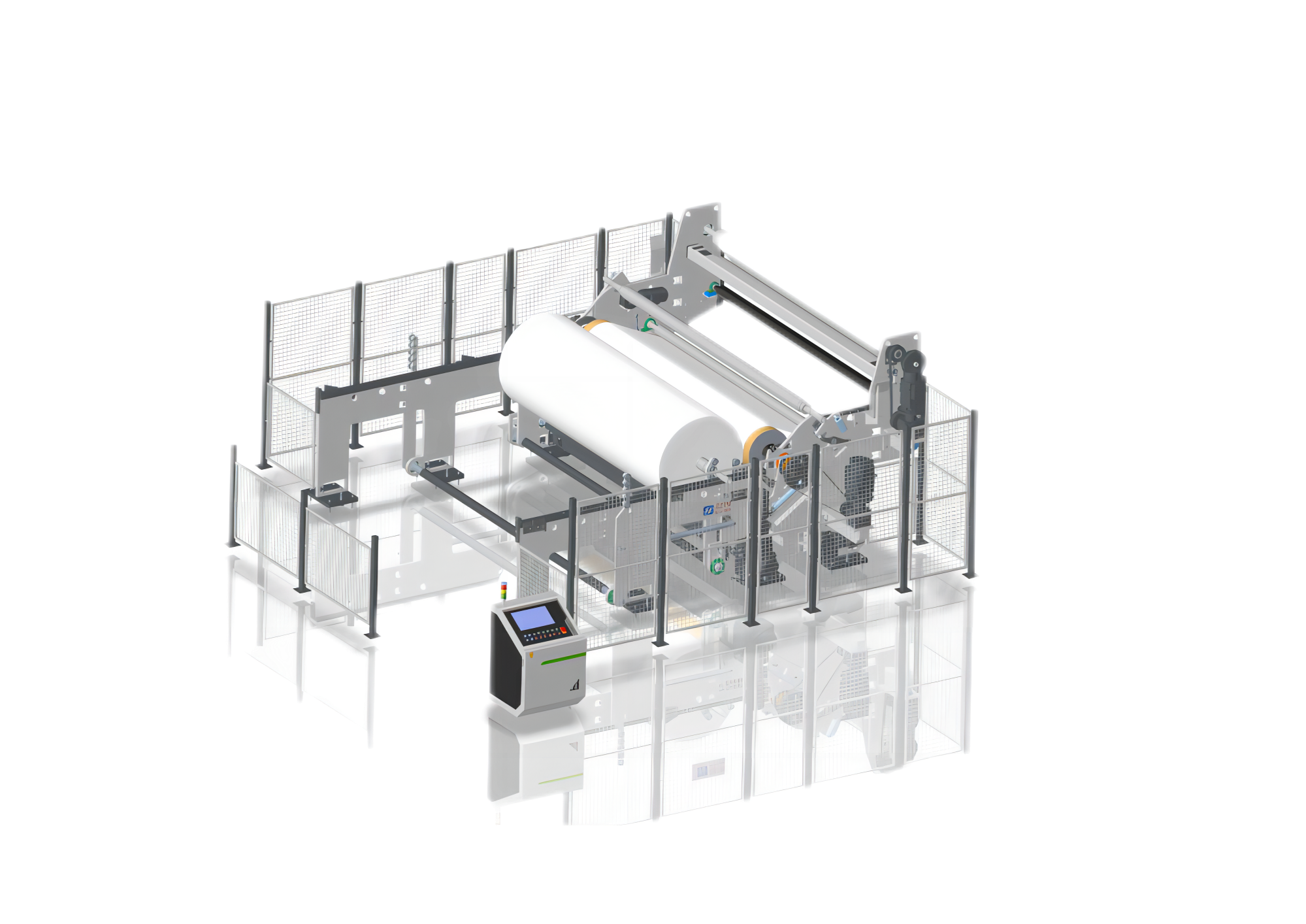

Isakhiwo:Indwangu engalukiweumshini wokuvalangokuvamile iqukethe izingxenye ezifana nohlaka, shaft emazombezombe, isistimu yokulawula ukungezwani, idivayisi yokusika ezenzakalelayo, kanye nesistimu yokulawula emazombezombe.I-shaft emazombezombe isebenza njengengxenye eyinhloko yokusonta kwendwangu engalukiwe futhi ingalungiswa ngobubanzi nobubanzi njengoba kudingeka.

Isimiso sokusebenza:Ngesikhathi sokusebenza, indwangu engalukiwe idluliswa isuka emshinini wokuphakela wangaphambili iye ku-shaft emazombezombe.I-uniform winding itholakala ngesistimu yokulawula ama-winging.Ngesikhathi esifanayo, uhlelo lokulawula ukushuba luqinisekisa ukuthi indwangu engalukiwe igcina izinga elifanele lokushuba ngesikhathi senqubo yokusonta ukuze kuvinjwe ukuxega noma ukulimala.

Ukusika Okuzenzakalelayo:Eminye imishini yokusonta indwangu engalukiwe ethuthukisiwe ifakwe umshini wokusika othomathikhi.Lolu cingo lungakwazi ukusika amaroli amanxeba abe ngobude obufunayo ngokusekelwe ezincazelweni ezisethwe ngaphambilini zokucubungula okulandelayo.

Uhlelo Lokulawula:Imishini yokusonta ngokuvamile ifakwe izinhlelo ezithuthukisiwe zokulawula ugesi ezivumela ukuzishintshanisa.Lawa masistimu avumela ukulungiswa nokuqapha amapharamitha njengesivinini sokuphenduka, ukushuba, nobude bokugoqa.

Izicelo:Imishini yokusonta indwangu engalukiwe ithola ukusetshenziswa okubanzi embonini yokukhiqiza indwangu engalukiwe, okuhlanganisa ukukhiqizwa kwempahla yezokwelapha, ama-napkins wenhlanzeko, izindwangu, izinto zokuhlunga, nokunye.Bangakwazi ukuhlalisa ububanzi obuhlukahlukene kanye nobubanzi bemiqulu.

Amapharamitha athile:

Imingcele ethile ye-aumshini wokusonta indwangu engalukiwezingahluka kuye ngomkhiqizi, imodeli, nokusetshenziswa okuhlosiwe.Nawa amanye amapharamitha ayisibonelo:

Ubukhulu.Roll Diameter:Ngokuvamile phakathi kwamamilimitha angu-200 (cishe amayintshi angu-8) kanye namamilimitha angu-800 (cishe amayintshi angu-31), kuye ngemodeli yomshini nokusebenza.

Ubukhulu.Roll Ububanzi:Ingase isukela kumamilimitha angu-1500 (cishe amayintshi angu-59) ukuya ku-5000 amamilimitha (cishe ama-intshi angu-197), kuye ngemodeli yomshini.

Isivinini Sokugoqa:Ngokuvamile phakathi kwamamitha angu-10 ngomzuzu (cishe amafidi angu-33 ngomzuzu) kanye namamitha angu-300 ngomzuzu (cishe amafidi angu-984 ngomzuzu), kuye ngemodeli yomshini.

I-Core Diameter:Ngokuvamile phakathi kwamamilimitha angu-50 (cishe amayintshi angu-2) kanye namamilimitha angu-152 (cishe amayintshi angu-6), kuye ngemodeli yomshini.

Imodi yokuphefumula:Izinketho zingafaka phakathi ukujikajika kohlangothi olulodwa, ukujikajika kwezinhlangothi ezimbili, okunye ukusonga, njll., kuye ngedizayini nenjongo yomshini.

Imodi yokusika:Eminye imishini ingase ifakwe umshini wokusika ozenzakalelayo wokusika lapho kudingeka khona.

Ukulawula Ukuqina:Ngokuvamile kufaka phakathi amasistimu okulawula ukushuba okuguquguqukayo ukuze kuqinisekiswe ukungezwani okufanele ngesikhathi sokusonga.

Uhlelo Lokulawula:Kufaka phakathi isixhumi esibonakalayo sesikrini esithintwayo, i-PLC (Isilawuli Se-Programmable Logic), njll., sokuzenzakalela nokulawula.

Izidingo zamandla:Ingadinga ukucaciswa kwe-voltage, imvamisa, namandla, ngokuvamile amandla ezigaba ezintathu.

Isisindo nobukhulu:Ubukhulu bomzimba nesisindo kuyahlukahluka kuye ngemodeli nomklamo, okudinga ukucatshangelwa kwesakhiwo nokufakwa efekthri.

umshini wokusonta indwangu engalukiwe, njengengxenye yomugqa wokukhiqiza indwangu engalukiwe, udlala indima ebalulekile ekuthuthukiseni ukusebenza kahle kokukhiqiza kanye nokuqinisekisa ikhwalithi yamaroli endwangu engalukiwe.Isebenza kulo lonke uhla lwezinqubo zokukhiqiza umkhiqizo wendwangu engalukiwe.

Sicela uxhumane noI-CTMTCuma kudingeka emshinini.

Isikhathi sokuthumela: Oct-09-2023